Wire Edm Definition

In other cutting operations such as lasers and abrasive water jet the larger the part the rougher the finish. Its innovative EDM technology uses a 0016 0400mm coated wire to achieve the fastest feedrates possible twice as fast as traditional 0010 brass wire.

Precision Wire Edm Machining Wire Edm Parts Ardel Engineering

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece.

Wire edm definition. Wire EDM machining Electrical Discharge Machining is an electro thermal production process in which a thin single-strand metal wire in conjunction with de-ionized water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining. The process is best suited for applications requiring low levels of residual stress.

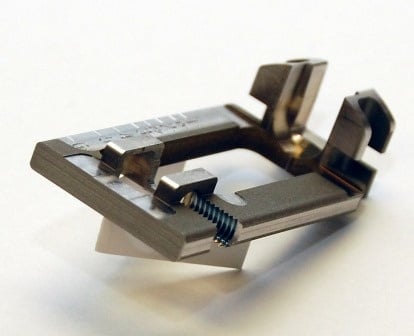

Wire EDM produces a smooth finish because the wire. For example a stamping die can be machined with 14 degree taper or a mold with one degree taper in some areas and two degrees in another with precision. Wire EDM produces an excellent finish even in the so-called rough cut Customers are often amazed when shown the fine finish of a single-pass cut.

Ad China Edm Wire Manufacturers Supplier High Quality Competitive Price. EDM can be used in everything from prototypes to full production runs and is most often used to manufacture metal components and tools. Short interesting video on the fundamentals of the electrical discharge machinin.

What is Wire EDM machining. Definition of Wire EDM. This fine finish is present even after very large parts are cut as in Figure 52.

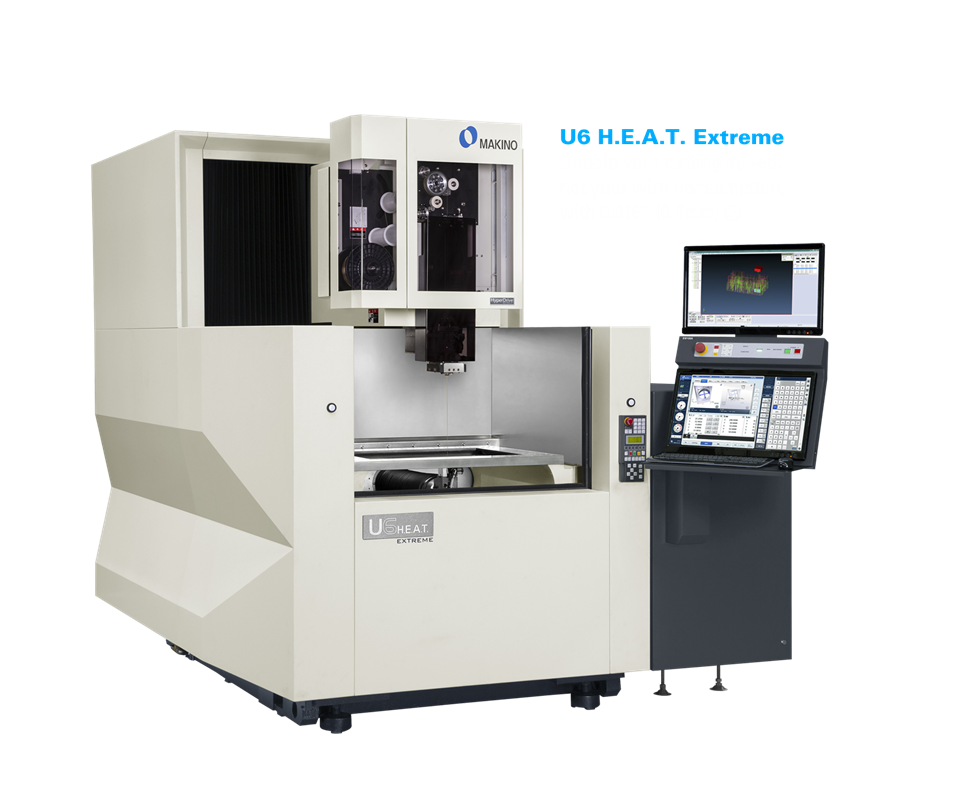

The workpiece is submerged in a dielectric fluid which increases the waters resistivity allowing for the generation of an arc at the wire which in turn disintegrates the workpiece. When the wire gets close to the part the attraction of electrical charges creates a controlled spark melting and vaporizing microscopic particles of. The Makino U6 HEAT.

All EDM machining is a thermalheat process that can alter or change the structure of the machined workpiece. It involves the use of a brass wire or thin copper to cut the workpiece. Due to the inherent properties of the process wire EDM can easily.

A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. Early EDM technology thermally damaged materials as a result of not controlling the discharge spark energy precisely enough. Wire EDM is most commonly used in mold and die manufacturing processes particularly for extrusion dies and blanking punches.

In wire electrical discharge machining WEDM also known as wire-cut EDM and wire cutting a thin single-strand metal wire usually brass is fed through the workpiece submerged in a tank of dielectric fluid typically deionized water. How does Wire EDM work. Basic introduction to the wire EDM and high-speed small hole EDM processes.

Wire EDM Method Wire EDM is a process whereby a thin wire is used as an electrode to cut along a programmed path. The resulting metallurgical quality produced by EDM can affect the workpiece function and lifecycle. Wire EDM machining Electrical Discharge Machining is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust.

Extrusion dies or nozzles and horns can be cut with constantly changing tapers. Extreme Wire Electrical Discharge Machine Wire EDM is the fastest in the industry. Wire EDM A non-traditional machining process that uses electricity to cut any conductive material precisely and accurately with a thin electrically charged copper or brass wire as an electrode.

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. The Spark Theory on a wire EDM is basically the same as that of the vertical EDM process. Sometimes referred to as wire erosion or spark EDM wire EDM is a popular process.

Wire Cut EDM Electrical Discharge Machining Image credit. Electrical Discharge Machining EDM a manufacturing process whereby a desired shape is obtained using electrical discharges is primarily used to cut hard metals and other materials that would be impossible to machine with traditional techniques. High frequency pulses of alternating or direct current is discharged from the wire to the workpiece with.

In wire EDM the conductive materials are machined with a series of electrical discharges sparks that are produced between an accurately positioned moving wire the electrode and the workpiece.

What Is Wire Edm Process Benefits Applications

What Is Wire Edm Process Benefits Applications

Electrical Discharge Machining Wikiwand

What Is Wire Edm A Guide To Wire Electrical Discharge Machining

What Is Electrical Discharge Machining And How Does It Work

Https Www Igi Global Com Viewtitle Aspx Titleid 271500

Posting Komentar untuk "Wire Edm Definition"